The wax project: from byproduct to architectural biomaterial

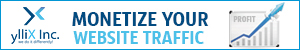

Plastic pollution poses one of the most pressing environmental challenges of the 21st century, impacting ecosystems, food systems, and human well-being. In response, The Wax Project led by MANUFACTURA offers an innovative sustainable solution by harnessing beeswax to create recyclable, translucent lattice panels. These 13 x 13 centimeter panels exemplify the potential of biomaterials in architecture as an alternative to traditional, polluting materials like acrylics, developed through 3D-printed prototypes and silicone molds. In collaboration with Gensler México and MATERIAM, the panels have been integrated into a prefabricated wooden lattice structure at the former’s México City office, showcasing the material’s natural aesthetic and sustainable benefits in a functional environment.

all images by GOGO Studio and Dinorah Schulte

Embracing beewax’s natural, renewable properties

Beeswax, a natural byproduct secreted by honeybees, is notable for its moisturizing, emollient, and softening properties. Its complex chemical structure, composed of esters and fatty acids, also offers unique. Addressing this, The Wax Project is a research and fabrication undertaking, where MANUFACTURA has explored the use of the material in architecture.

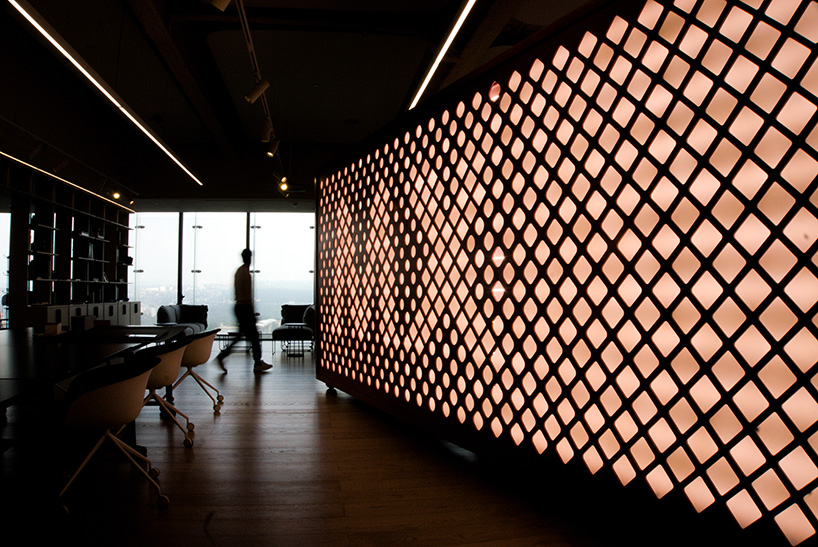

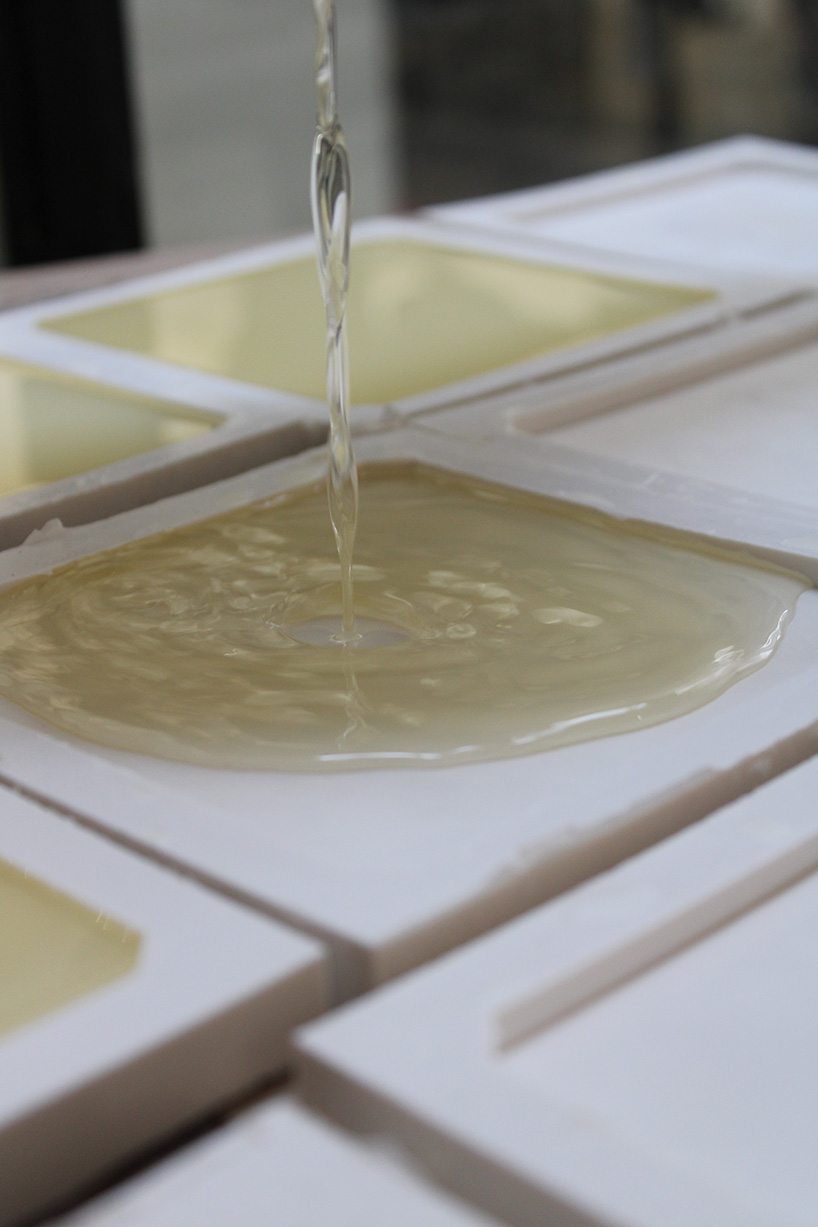

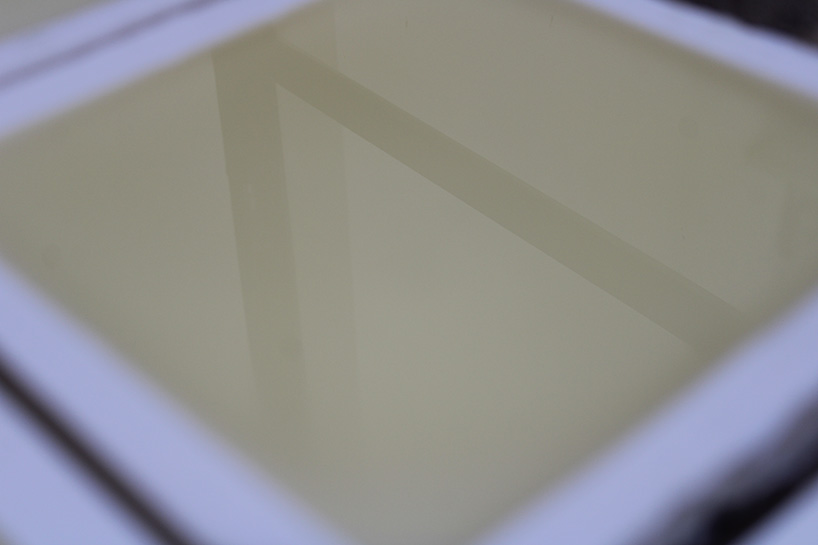

These lattices allow the passage of light and, at the same time, have a rigid surface, which makes them suitable for use as construction elements. Unlike acrylics and plastics, beeswax allows for easy reuse, since in case of damage, a new panel can be produced in less than 30 minutes, significantly reducing the carbon footprint. The manufacturing process of these lattices consists of several stages: the natural wax is ground and heated and stearic acid is added to improve its rigidity. The mixture is then poured into the silicone mold and left to cool for 40 minutes. The result is sustainable panels ready for indoor

realized by MANUFACTURA, Gensler México, and MATERIAM

realized by MANUFACTURA, GENSLER México, and MATERIAM

The assembly component of the project was completed alongside Gensler México, a collaborative design firm that unites creativity, research, and innovation to solve complex problems with a humanist approach. The panels were integrated into a prefabricated wooden structure made in collaboration with MATERIAM, complemented with LED lighting to highlight the lattice in the interior of Gensler office located in Mexico City.

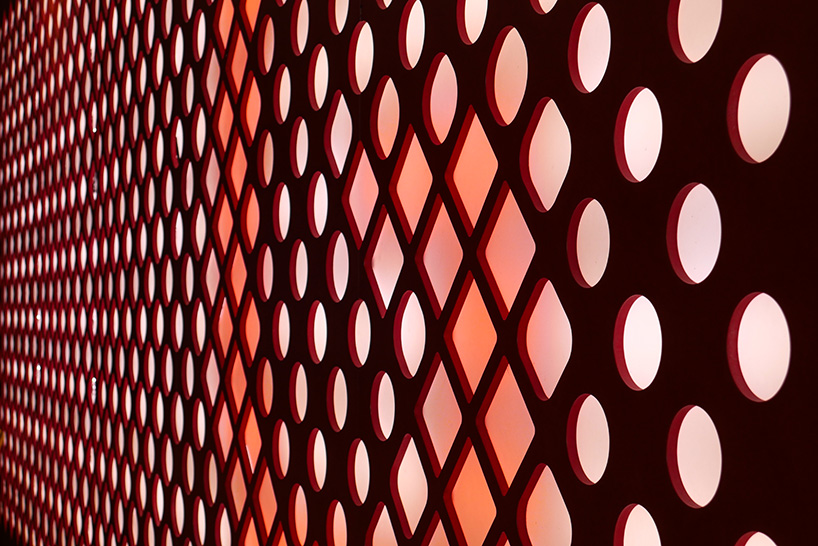

This work not only demonstrates the feasibility of using wax in architecture, but also emphasizes environmental responsibility by substituting polluting materials such as acrylic, contributing to a more environmentally conscious and respectful design. ‘Using beeswax in architecture is not only a technical or functional solution, it is a declaration of principles. This material invites us to rethink the way we build and live, prioritizing harmony with the environment and respect for natural resources,’ notes the team at MANUFACTURA. Unlike acrylic, wax is not only sustainable, but it brings a handcrafted and warm dimension to the spaces it transforms.

the wax lattice wall at the México office

LED lighting highlights the panels

details of the final prototype of The Wax Project

the project harnesses beeswax to create recyclable, translucent lattice panels

developed through 3D-printed prototypes and silicone molds

beeswax blocks

a new panel can be produced in less than 30 minutes, significantly reducing the carbon footprint

casting process

wax lattice drying

project info:

name: The Wax Project

designer: MANUFACTURA

collaborator: Gensler México | @gensler_design, MATERIAM | @materiamfab

MANUFACTURA team: Dinorah Schulte (CEO, Founder), Jared Zarate, Erick Marin, Jorge Orduña

Gensler México team: Alejandra Diaz de Leon (design technology strategist), Alan Haquet (architect), Ana Karen Rodriguez (project architect), Ander Anasagasti (architect), Fernanda Solano (architect), Nadja Borras (design director)

MATERIAM team: Laura Elena Ayala Medina Mora (design director), Sergio Javier Bello Hernández (engineer leader), Axel Ricardo Garcia Gonzalez (engineer), Edgar Alejandro Gonzalez Rosas (technician), Jose Ricardo Ramirez Velazquez (technician), Cristian Reynaldo Rios Garcia (technician),

material research and prototype design: Manuela Garcia

material research and production: Los Veleritos

photography: GOGO Studio, Dinorah Schulte

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: ravail khan | designboom